AR Lower Receivers: Cast vs Billet (6061-T6) vs Forged (7075-T6) Aluminum

Posted by 80-Lower.com on Jul 30th 2020

The most important part of the AR-15, the lower receiver (the firearm itself) is most often made from two types of metal alloys: Billet (6061-T6) and forged (7075-T6) aluminum. If you're here, you're probably going to build your AR-15 using an 80% lower. If that's the case, choosing between billet and forged aluminum becomes an important decision: You're not just buying a rifle, you're cutting and drilling the receiver with hand tools. That means these alloys' properties will play a part in the project. We're also covering cast lowers in this guide. Let's compare them all so you know which one to pick.

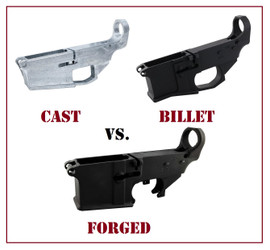

Cast vs Billet vs Forged

These three terms, "billet", "forged", and "cast", refer not to the aluminum's composition but to how each type of receiver is manufactured. We'll also cover their chemical composition and mechanical properties to compare and contrast each alloy.

Cast Aluminum

Cast receivers are made by melting A380 aluminum alloy and pouring it into a receiver-shaped mold. The mold produces the rough exterior of the receiver. The receiver's final shape is made by CNC machining the receiver. This process also fabricates the magazine and bolt catch mounting locations, the various holes for inserting detents and springs, and the buffer tube housing and threads. Despite their fabrication process, cast lowers appear exactly the same as a billet or forged receiver because of this CNC machining process (and because any type of AR lower usually receives the same anodized coating).

A380 Chemical Composition

- Aluminum (Al): 80.3 - 89.5 %

- Copper (Cu): 3.0 - 4.0 %

- Iron (Fe): <= 1.3 %

- Magnesium (Mg): <= 0.5 %

- Manganese (Mn): <= 0.5 %

- Silicon (Si): 7.5 - 9.5 %

- Tin (Sn): <= 0.35 %

- Zinc (Zn): <= 3.0 %

A380 Mechanical Properties

- Hardness (Brinell): 80

- Tensile Strength: 47,000 PSI

- Yield Strength: 23,100 PSI

- Fatigue Strength: 20,000 PSI

- Shear Strength: 26,800 PSI

- Melting Point: 1,100 (F)

Cast Pros

A380 provides a good compromise of casting quality and overall mechanical and thermal properties. Basically, it provides a good balance of strength and resistance to heat while allowing for relatively precise and consistent castings to be poured. Because its fabrication is so simple, the cost of production -- and for you, the cost of the lower receiver -- is low. In fact, the cost of a cast lower may be less expensive than any forged or billet lower, if you can find one still being produced (that's a segue into our cons).

Cast Cons

While A380 is a wonderful alloy still used by the automotive and tool industry, it has fallen out of favor in the firearm industry for one simple reason: Forged and billet receivers have become incredibly cheap to make. Compared to either of the other two types, a cast receiver won't be as strong, either. The casting process can create imperfections in the receiver, like small cracks, fissures, and hollow cavities. These can weaken the receiver and even cause a catastrophic failure when placed under extreme stress (such as when handling semiautomatic fire in an AR).

Billet Aluminum

A billet lower receiver is formed from a solid block of extruded 6061-T6 aluminum called bar stock. This 6061 bar stock is incredibly strong because of its fabrication process: Extrusion requires heating the aluminum to soften it before forcing it through a shaped die smaller in diameter than its current shape, compressing the alloy and hardening it. This roughly extruded aluminum is then fabricated into the shape of the lower receiver with its final form and all other integrated components cut via CNC machining.

6061-T6 Chemical Composition

- Aluminum (Al): 95.8 - 98.6 %

- Chromium (Cr): 0.04 - 0.35 %

- Copper (Cu): 0.15 - 0.4 %

- Iron (Fe): <= 0.7 %

- Magnesium (Mg): 0.8 - 1.2 %

- Manganese (Mn): 0.15 %

- Silicon (Si): 0.4 - 0.8 %

- Titanium (Ti): <= 0.15 %

- Zinc (Zn): <= 0.25 %

6061-T6 Mechanical Properties

- Hardness (Brinell): 95

- Tensile Strength: 45,000 PSI

- Yield Strength: 40,000 PSI

- Fatigue Strength: 14,000 PSI

- Shear Strength: 30,000 PSI

- Melting Point: 1,205 (F)

Billet Pros

Because 6061 is heat-treated extensively, it produces the greatest possible tensile and yield strength. A higher yield strength allows the alloy to withstand more abuse and deformation without risking damage, like cracking or bending. 6061 is also highly corrosion resistant and maintains great enough heat resistance that it's now a popular material in suppressor baffles and spacers. Its machining process also provides some unique advantages for the billet lower receiver, like being easily designed and fabricated with complex shapes or features. Some billet receivers sport custom magazine wells and patterns, while others have integrated trigger guards or have had their roll pin fittings upgraded with threaded fittings.

Billet Cons

Billet receivers are more expensive to produce than forged and cast receivers, so they typically cost more. Part of this cost increase can also often be attributed to some of those unique features described above. For some, those extra features can make install and assembly easier. For others, it's unnecessary. Billet receivers will also not be guaranteed to be compatible with mil-spec AR components, which make up a bulk of the market. You'll need "commercial"-sized components, including a larger buffer tube.

Forged Aluminum

Forged receivers are made from 7075-T6 aluminum which is heated and hammered under intense pressure into a mold to achieve its final shape. Once cooled, the roughly formed receiver is cleaned up with CNC in similar fashion to a cast receiver, with all integrated parts cuts and threaded. This age-old manufacturing process is simple and affordable and produces an incredibly tough lower receiver. Forged receivers are the only type considered "mil-spec", utilizing the same diameter buffer tube and other fittings as a military-issue M4 or M16 lowers. However, most forged 80% lowers and any receivers made for consumers do not have the capacity to accept an M16 or full-auto parts kit.

7075-T6 Chemical Properties

- Aluminum (Al): 87.1 - 91.4 %

- Chromium (Cr): 0.18 - 0.28 %

- Copper (Cu): 1.2 - 2.0 %

- Iron (Fe): <= 0.5 %

- Magnesium (Mg): 2.1 - 2.9 %

- Manganese (Mn): <= 0.3 %

- Silicon (Si): <= 0.4 %

- Titanium (Ti): <= 0.2 %

- Zinc (Zn): 5.1 - 6.1 %

7075-T6 Mechanical Properties

- Hardness (Brinell): 150

- Tensile Strength: 83,000 PSI

- Yield Strength: 73,000 PSI

- Fatigue Strength: 23,000 PSI

- Shear Strength: 48,000 PSI

- Melting Point: 1,175 (F)

Forged Pros

Metallurgists agree that a forged piece of aluminum is stronger than cast or billet. The reason being, when the material is shaped under pressure, its 'grain' follows the same shape as the part. As a result, the product manufactured is stronger due to the continuous grain characteristics allowed by the forging process. Forged receivers are also typically smaller in exterior dimension than billet or cast receivers. These units are typically the most affordable and they're always mil-spec, ensuring greater parts compatibility compared to cast or billet lowers.

Forged Cons

Forged receivers suffer no real "cons" or drawbacks for the end-user, whether configured as a stripped receiver or an 80% unit. They may not enjoy the same level of precision-machined aesthetics as a billet receiver, and they won't typically come with upgrades like integrated trigger guards or threaded fittings where roll pins are normally used.

Heat-Treating and the "T6" Temper

It's important to note these two alloys' properties are only achieved by heat-treating both alloys to improve their strength. Heat-treated alloys are given "T" temper codes, ranging from T1 to T10:

- T1 - Cooled from an elevated temperature shaping process. Naturally aged to a stable condition.

- T2 - Cooled from an elevated temperature shaping process. Cold-worked and aged to a stable condition.

- T3 - Solution heat treated, cold worked, and naturally aged to a substantially stable condition.

- T4 - Solution heat treated, and naturally aged to a substantially stable condition.

- T5 - Cooled from an elevated temperature shaping process then artificially aged.

- T6 - Solution heat treated then artificially aged.

- T7 - Solution heat treated then overaged/stabilized.

- T8 - Solution heat treated, cold worked, then artificially aged.

- T9 - Solution heat treated, artificially aged, then cold worked.

- T10 - Cooled from an elevated temperature shaping process, cold worked, then artificially aged.

To achieve a T6 temper, the billet or forged aluminum is heated to 990 degrees (F) for one hour. This dissolves the elements (magnesium, zinc, silicon) in the metal into a "solid solution", creating a uniform grain structure - an orderly array of atoms - strengthening the metal considerably. It's then quenched rapidly in cold water to prevent those dissolved elements from "precipitating" (seeping out) of the metal. Once cooled, the metal is then artificially aged in a large oven, heated to 350 degrees (F) for about 8 hours. This increases the typical yield strength substantially. The yield strength is the true working strength of the receiver - that is, how much force it can withstand before permanently deforming, bending, or cracking under pressure.

Which is Better? Forged or Billet?

For even more detailed comparisons, check out the Spec Sheets for both alloys here:

- 6061-T6 – https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA6061t6

- 7075-T6 – https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA7075T6

At first glance, it looks like forged aluminum is the clear winner if you're building an AR-15: 7075-T6 boasts higher hardness rating, so it'll withstand direct impacts, scratches and dents more easily. The higher strength ratings mean it can also take more abuse in the field.

Many machinists say 6061 is a little easier to cut and drill.

If you're building an 80% lower, it's the machinability of that lower receiver that'll make or break your project. If you're inexperienced with drilling and cutting metal, you want a receiver that's as easy as possible to fabricate. The softer billet aluminum is easier to work through and causes less wear-and-tear on carbide drill bits and end mill bits. It's also less prone to causing tool "chatter", vibrations that can occur in your bits, router, or drill press when tool pressure is too high. Because it's slightly softer, billet aluminum is typically more forgiving on your tools. It is slightly easier to cut and drill than forged aluminum, so if you're looking for the simplest 80% lower to machine, stick with a billet unit.

Summary

Although personal preference will ultimately be the deciding factor as to what lower receiver you purchase, each method of manufacturing offers some form of benefit. While there has been great debate between the loyalists of each manufacturing process, few can attest to the failure of any lower that has been purchased from a quality manufacturer. If you have questions regarding our lower receivers, please feel free to contact us.

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At 80-lower.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.